Due to high shipping cost, it is advisable to find a source of posts locally.

Some general guidelines of what we find works in most circumstances is discussed below. This information is offered for budget purposes only. The type, size of post, and footing details are best obtained using a licensed engineer.. Engineering services are available for a fee through us.. Provide a scale drawing or sketch of your project to get a quote. Fees usually range from $800-$2500.

In general, for “Ready Made” sails, we usually use 4″ schedule 40 steel pipe (galvanized) or wooden temporary power poles (treated) that are 6″ or larger. Steel posts can be powder coated or painted to help protect them and provide the desired color. Steel pipe

is usually found at a steel supply or pipe supply vendor. (Not at Home Depot) If timber posts are used, then we generally recommend temporary power poles with a preservative added to the wood. Don’t use dimensional lumber as it is not strong enough.

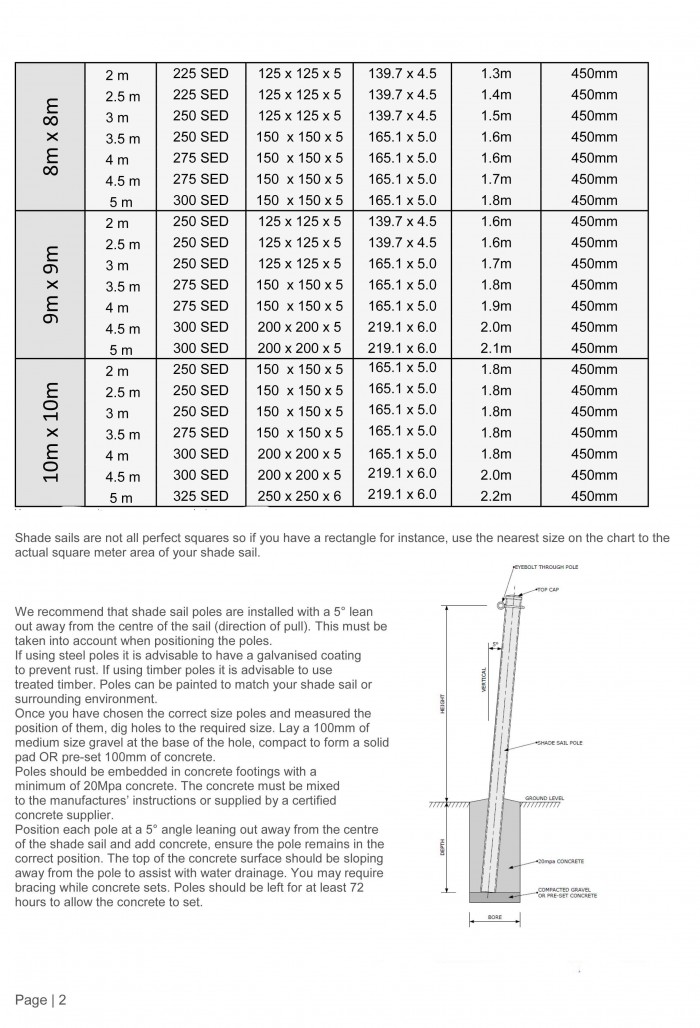

Plumb or slightly lean back the post and support it until the concrete has dried. If the posts are taller than 12’ or more than one sail is attached to the same post then larger diameter posts are usually required and you should have the job engineered. Larger

post should also be used with larger custom sails.

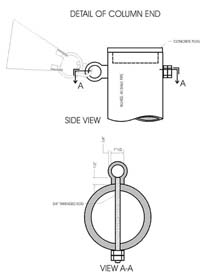

Install Eye nuts with threaded rod through the posts with the eyes pointed at the center of the sail.

If you need to cut the steel pipe then we use either an angle grinder or circular saw with a metal cutting blade.

Depending on the height, posts are usually embedded in a concrete footing, 3 ft. to 6 ft. deep and 1 ft. to 1.5 ft. in diameter. (Generally a third of the total length of the post is embedded…. So for example, a 10’ high post should have about 5’ in the

ground). If you skimp on depth the post will get pulled over.

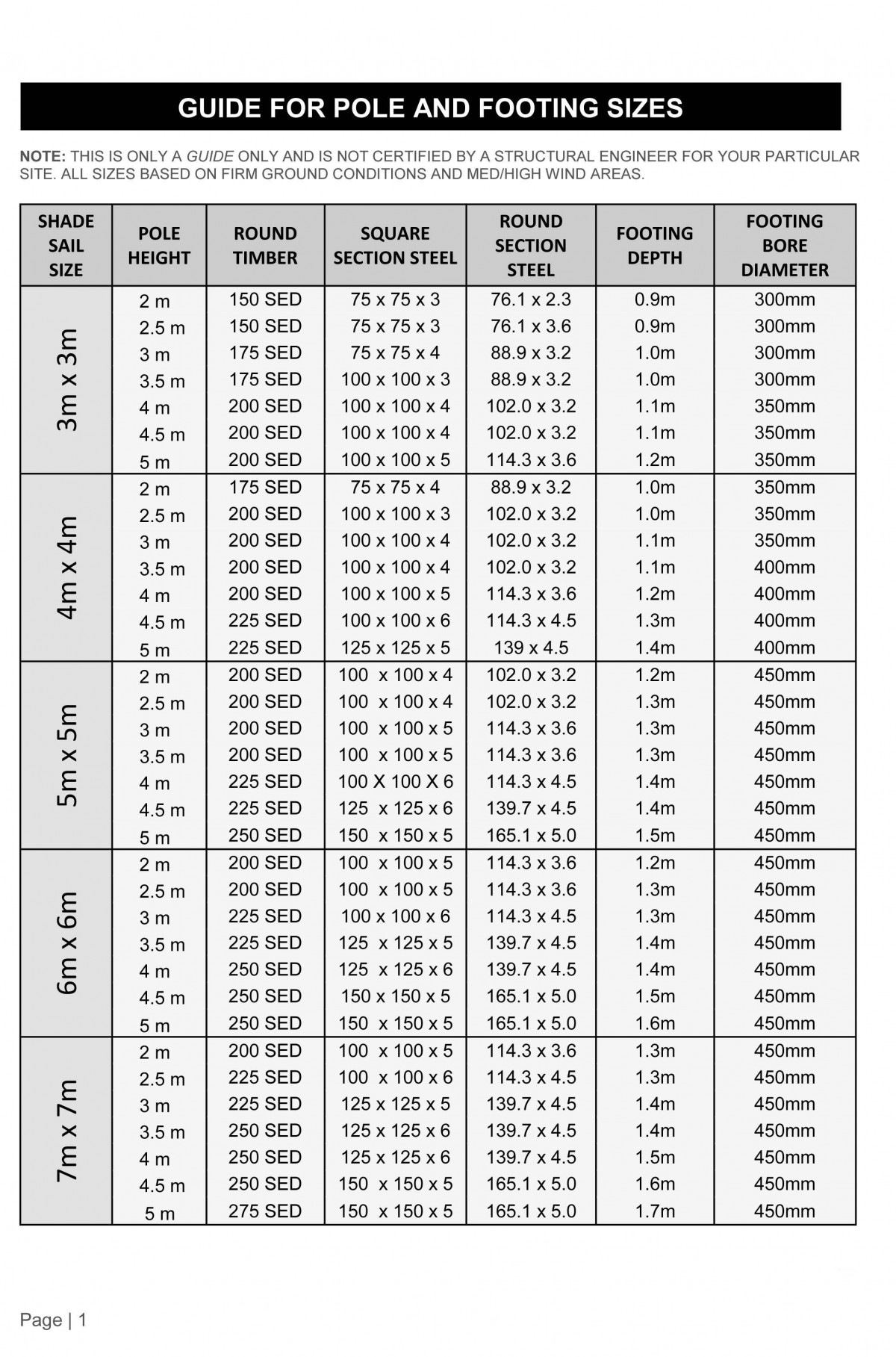

Pole Guide below is in metric.